The major advantages of hydraulic synchronous clamp when compare to the traditional clamp:

Centering and vising function: Its two pawls move synchronously back and forth. Even there is some deviation for the workpiece shape or the shape is not regular, self-centering vise system can insure the center of workpiece always being held. (Center zero point remains the same.) The processing based on the center point can be carried out. The high Precision of vising and repeated positioning insures the prec ision of processed workpiece. Make the pawl according to the shape of workpiece and you can process the different shape workpiece only with the pawl replacing. The center point remains the same after pawl replacing. It is convenient and fast for the new operator and cost can be down.

High strength of vising: It can reach 0-2200 kg/cm² (Type:HSC-40) with the hydraulic pressure supply 70 kg/cm² and can be free adjusted by the pressure adjusting valve.

Surface is flat for easily clean. There are two ways designed to make the excellent effect of dust and water proof. It can work under bad environment without clamp deactivation. It is also equipped inlet hole for lubricant so it is convenient for lubrication to insure longer life.

Wide range of vising : The length can be 480mm and the diameter of various irregular shape workpiece can be 200mm.

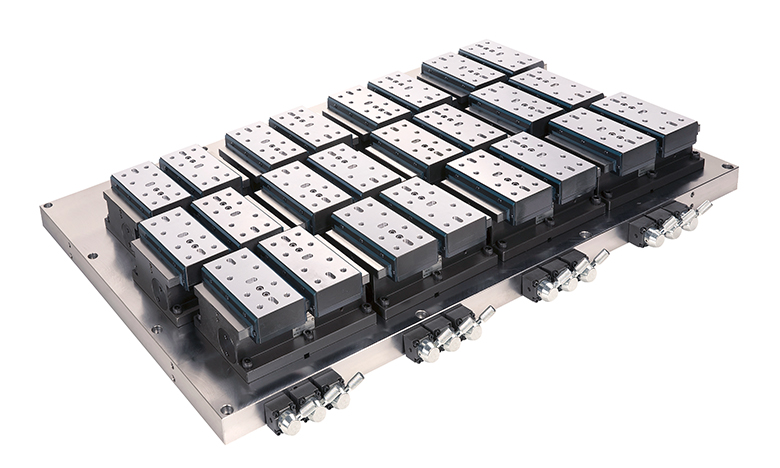

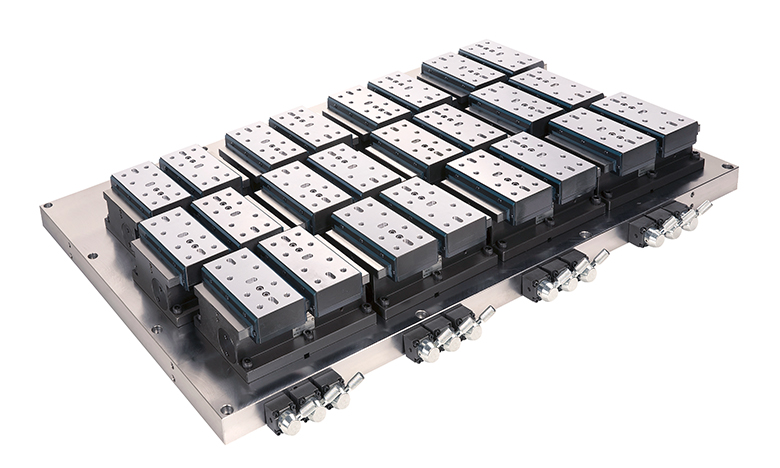

The hydraulic synchronous clamp has standardized specification and compact structure. It makes the quantity of available clamps in limited space be higher. For example, on a 1200 X 600mm working table at least 25 hydraulic synchronous clamps (Type:HSC-25) can be equipped. It also makes that at the same time various workpieces can be processed on one working table which means higher effect of production.

Processing can be stopped anytime in order to insert urgent order. Because the datum point is fixed and repeated positioning accuracy, you can only need to change the pawls to do the processing again without correction or re-adjustment.

The advantages brought by hydraulic synchronous clamp for production:

Speed : Because no need to do re-correction setting for the only one datum point, it reduces the shutdown time needed for working table pre-adjustment and increase the processing speed substantially.

Reduce the investment for working table: Because the pre-adjustment time reducing and the quantity of workpiec3e increasing on the working table, it increases the percentage of working table utilization. The customer will relatively reduce the investment for working table and no influence for the production efficiency. The investment cost will be reduced.

Reduce the labor cost: Because the pre-adjustment time reducing, human resource can be arranged reasonably. One labor can control many working tables and number of labor scan be reduced.

Human error reducing: Because of automation and standardized mode, it can reduce human error and increase the yield rate, production and quality assurance.

Increase the percentage of working table utilization: When CNC processing finished, after pawl changing you can go on other processing, it is convenient even if it is necessary to put on pawl again and rework. It increases the percentage of working table utilization effectively. During the above period, it is not necessary to change the whole complicated mould and it reduces the cost.

Material saving: The processing uses center as datum point can be done and won’t cause big-small effect. For the casting workpiece, no need to reserve thick edge.

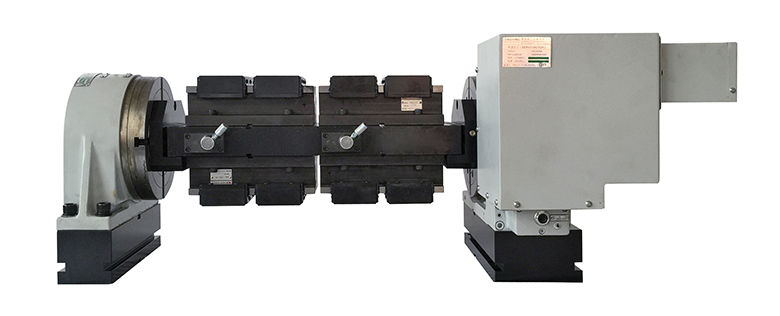

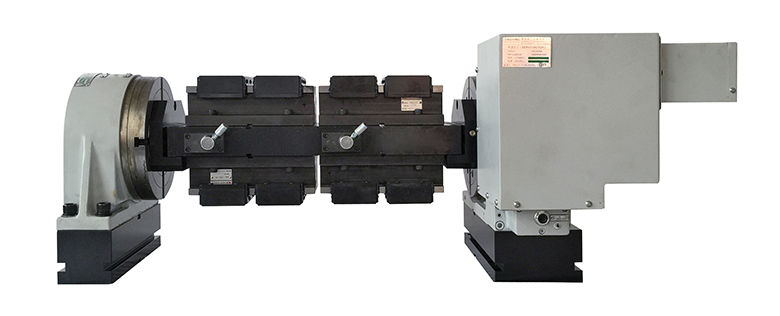

Use hydraulic synchronous clamp on CNC central fourth axis can as much as possible to reduce number of pawl mounting and processes 3 surfaces after first pawl mounting.

On the same working table, you can process different workpieces with different pawls made according to its shape. This will increase the clamp utilization.

Intangible benefit: Your hydraulic synchronous clamp using will increase your customer’s confidence while they visiting your factory, it will increase competitiveness for your company.

Face to the future: Because hydraulic synchronous clamp uses hydraulic power supply, it can be standardized and automated. The control system can be connected with CNC panel box; it will help you to realize the robot automatic production.

Specifications:

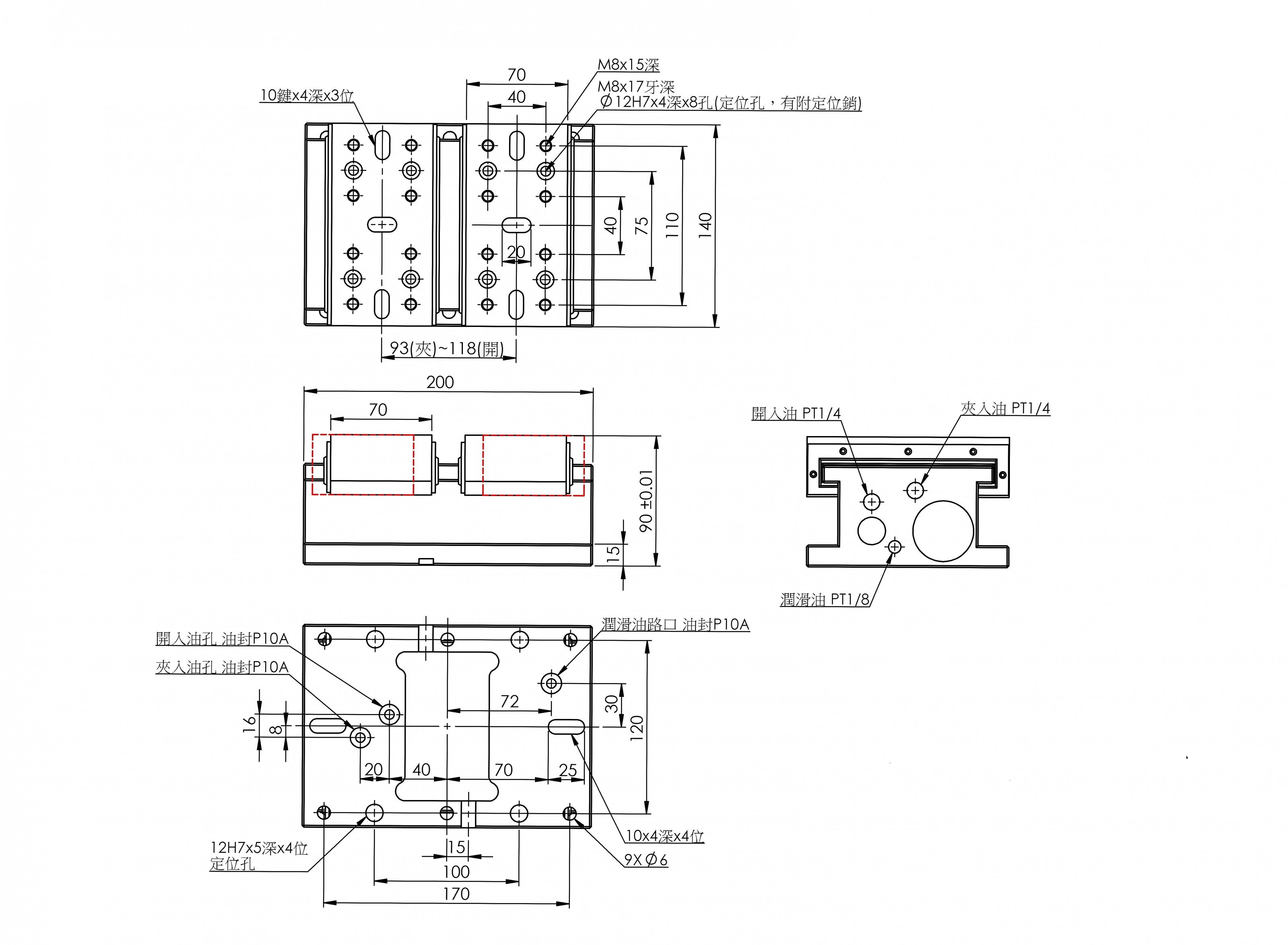

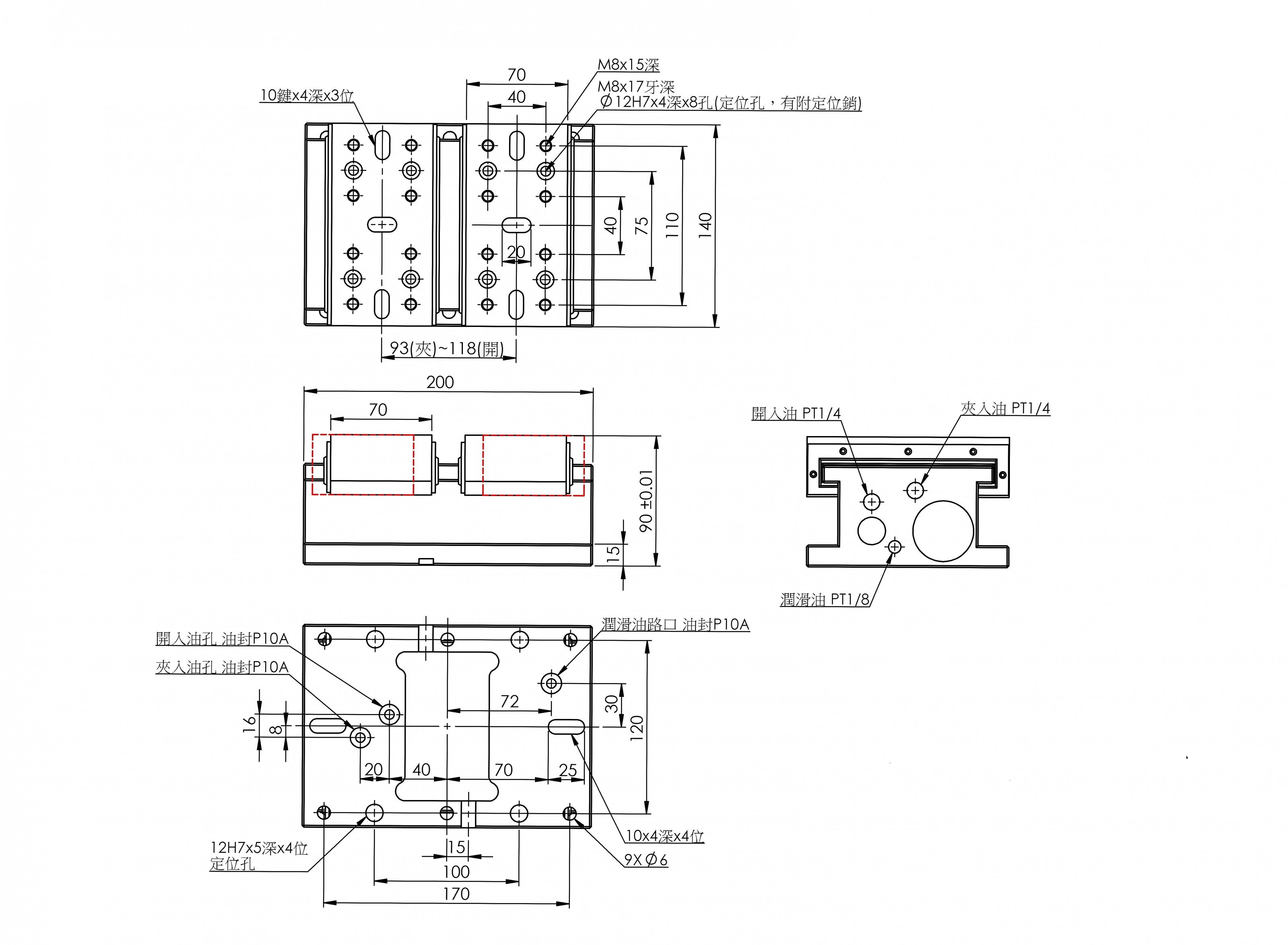

External size Drawing:

Tooling Sample Of Live:

Application case: Installed on CNC processing table

Application case: Installed on CNC fourth axis

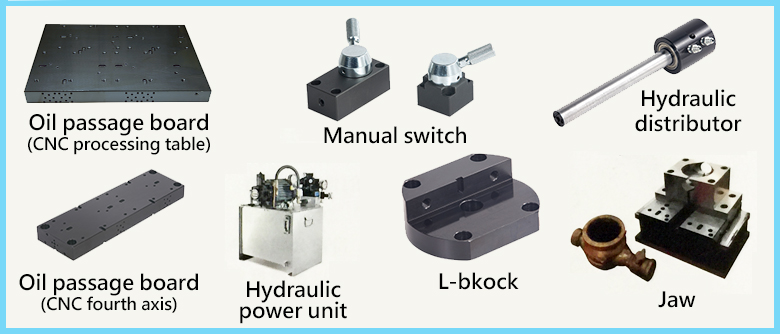

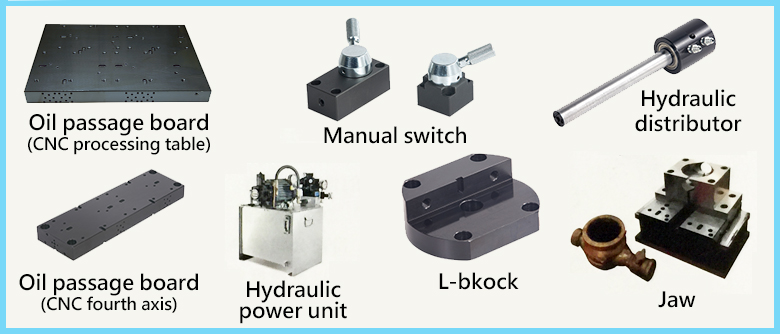

Peripheral Accessories:

The Sample Parts Of The Raw:

Operating demonstration:

Centering and vising function: Its two pawls move synchronously back and forth. Even there is some deviation for the workpiece shape or the shape is not regular, self-centering vise system can insure the center of workpiece always being held. (Center zero point remains the same.) The processing based on the center point can be carried out. The high Precision of vising and repeated positioning insures the prec ision of processed workpiece. Make the pawl according to the shape of workpiece and you can process the different shape workpiece only with the pawl replacing. The center point remains the same after pawl replacing. It is convenient and fast for the new operator and cost can be down.

High strength of vising: It can reach 0-2200 kg/cm² (Type:HSC-40) with the hydraulic pressure supply 70 kg/cm² and can be free adjusted by the pressure adjusting valve.

Surface is flat for easily clean. There are two ways designed to make the excellent effect of dust and water proof. It can work under bad environment without clamp deactivation. It is also equipped inlet hole for lubricant so it is convenient for lubrication to insure longer life.

Wide range of vising : The length can be 480mm and the diameter of various irregular shape workpiece can be 200mm.

The hydraulic synchronous clamp has standardized specification and compact structure. It makes the quantity of available clamps in limited space be higher. For example, on a 1200 X 600mm working table at least 25 hydraulic synchronous clamps (Type:HSC-25) can be equipped. It also makes that at the same time various workpieces can be processed on one working table which means higher effect of production.

Processing can be stopped anytime in order to insert urgent order. Because the datum point is fixed and repeated positioning accuracy, you can only need to change the pawls to do the processing again without correction or re-adjustment.

The advantages brought by hydraulic synchronous clamp for production:

Speed : Because no need to do re-correction setting for the only one datum point, it reduces the shutdown time needed for working table pre-adjustment and increase the processing speed substantially.

Reduce the investment for working table: Because the pre-adjustment time reducing and the quantity of workpiec3e increasing on the working table, it increases the percentage of working table utilization. The customer will relatively reduce the investment for working table and no influence for the production efficiency. The investment cost will be reduced.

Reduce the labor cost: Because the pre-adjustment time reducing, human resource can be arranged reasonably. One labor can control many working tables and number of labor scan be reduced.

Human error reducing: Because of automation and standardized mode, it can reduce human error and increase the yield rate, production and quality assurance.

Increase the percentage of working table utilization: When CNC processing finished, after pawl changing you can go on other processing, it is convenient even if it is necessary to put on pawl again and rework. It increases the percentage of working table utilization effectively. During the above period, it is not necessary to change the whole complicated mould and it reduces the cost.

Material saving: The processing uses center as datum point can be done and won’t cause big-small effect. For the casting workpiece, no need to reserve thick edge.

Use hydraulic synchronous clamp on CNC central fourth axis can as much as possible to reduce number of pawl mounting and processes 3 surfaces after first pawl mounting.

On the same working table, you can process different workpieces with different pawls made according to its shape. This will increase the clamp utilization.

Intangible benefit: Your hydraulic synchronous clamp using will increase your customer’s confidence while they visiting your factory, it will increase competitiveness for your company.

Face to the future: Because hydraulic synchronous clamp uses hydraulic power supply, it can be standardized and automated. The control system can be connected with CNC panel box; it will help you to realize the robot automatic production.

Specifications:

| Model | Jaw stroke | Max. pressure | Max. clamping force | Reproducibility | Weight |

| HSC-25 | 25 mm | 40 kg/cm² | 380 kgf | ±0.01 mm | 13 kg |

External size Drawing:

Tooling Sample Of Live:

Application case: Installed on CNC processing table

Application case: Installed on CNC fourth axis

Peripheral Accessories:

The Sample Parts Of The Raw:

Operating demonstration: